Powder coating is one of the most reliable finishing methods used across industrial environments because…

In the world of industrial painting, achieving a flawless finish is paramount. Downdraft paint booths have become a popular solution for various applications, especially in industries such as automotive and aerospace. This blog explores what a downdraft paint booth is, its features, benefits, and common applications, helping you understand why it might be the right choice for your painting needs.

Table of Contents

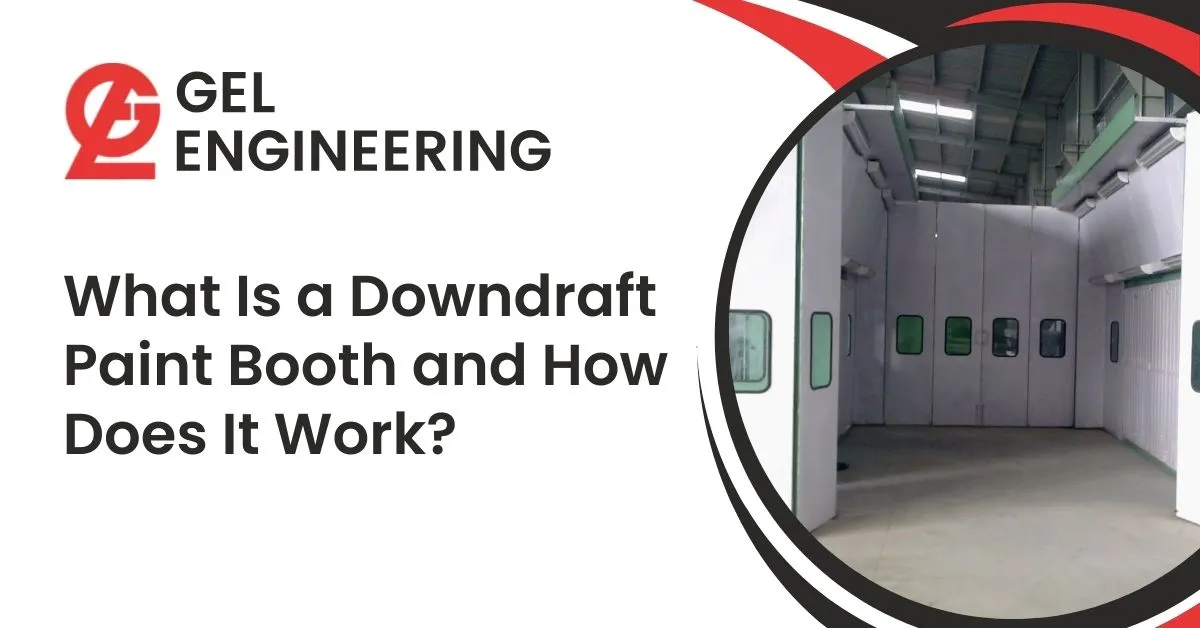

What is a Downdraft Paint Booth?

A downdraft paint booth is a specialized enclosed space designed for spray painting and finishing applications. The defining characteristic of this booth is its airflow system, which pulls air from the top of the booth down through the workspace, effectively removing overspray and contaminants. This controlled airflow not only enhances the quality of the finish but also ensures a safer and cleaner working environment.

Key Features of Downdraft Paint Booth

- Airflow Design

The downdraft design features exhaust vents located at the booth’s floor level. As air is drawn from the ceiling and flows downward, it creates a smooth, laminar airflow that minimizes turbulence and ensures that paint particles are effectively captured before they settle on the surface being painted. - Filtration Systems

Downdraft booths are equipped with advanced filtration systems that trap overspray and particulate matter. These systems typically include pre-filters and high-efficiency particulate air (HEPA) filters to ensure clean air is recirculated back into the environment. - Temperature and Humidity Control

Many modern downdraft booths come with built-in heating systems to maintain optimal temperatures for drying and curing paints. Some models also include humidity control features, which are essential for achieving the best finish quality. - Customizable Design

Downdraft booths can be customized to accommodate specific needs, including size, ventilation capacity, and additional features such as LED lighting, touch control panels, and advanced monitoring systems.

Benefits of Downdraft Paint Booth

- Superior Finish Quality

The controlled airflow minimizes the risk of dust and debris settling on freshly painted surfaces, resulting in a smoother and more uniform finish. This is particularly crucial in industries where aesthetics and performance are paramount, such as automotive and aerospace. - Increased Safety

By effectively removing overspray and harmful vapours, downdraft booths create a safer working environment for operators. The enclosed design and filtration systems reduce the risk of accidents and health hazards associated with inhaling paint fumes. - Efficiency and Productivity

The efficient airflow and temperature control enable faster drying times, allowing for quicker project turnaround. This efficiency helps businesses improve their productivity and overall output. - Environmental Compliance

Downdraft booths are designed to comply with environmental regulations by capturing and containing VOCs (volatile organic compounds) and other pollutants, helping companies maintain compliance with local laws.

Common Applications of Downdraft Paint Booth

- Automotive Painting

Downdraft paint booths are widely used in automotive refinishing and manufacturing, where high-quality finishes are essential. They are ideal for painting vehicle bodies, parts, and accessories. - Aerospace Manufacturing

In the aerospace industry, downdraft booths ensure that aircraft components receive superior coatings that withstand rigorous standards. The ability to maintain strict environmental controls is crucial in this sector. - Industrial Coating

Downdraft booths are also utilized in various industrial coating applications, including machinery, equipment, and structural components, where durability and appearance are critical. - Furniture Finishing

The furniture industry benefits from downdraft paint booths for achieving high-quality finishes on wooden and metal products, reducing the likelihood of imperfections.

Frequently Asked Questions

What is the purpose of a paint booth?

The purpose of a paint booth is to create a controlled environment for painting, minimizing contamination and ensuring high-quality finishes while providing ventilation and safety for workers.

How does a downdraft booth work?

A downdraft booth works by drawing air from the ceiling and directing it downwards through the workspace, capturing overspray and contaminants before they settle on painted surfaces, thereby maintaining a clean environment.

What happens in a downdraft?

In a downdraft booth, air is pulled from the ceiling down through the workspace, effectively capturing paint overspray and dust. This airflow, combined with filtration systems, ensures a clean environment that enhances finish quality and safety.

Conclusion

A downdraft paint booth is an excellent investment for businesses looking to enhance their painting processes. Its superior airflow design, advanced filtration systems, and ability to maintain optimal working conditions make it a preferred choice for various applications. Whether you operate in the automotive, aerospace, or industrial sector, a downdraft paint booth can significantly improve your finish quality, safety, and productivity.

If you’re considering upgrading your painting facilities or investing in new equipment, a downdraft paint booth could be the perfect solution. Explore your options today and experience the benefits of this advanced painting technology!