In industrial spray painting, finish quality depends not only on paint material and technique but…

In industries where precision and cleanliness are crucial, conveyorized washing machine and industrial parts washing machines have revolutionized the cleaning process. These automated systems ensure high performance, consistent cleaning, and operational efficiency, making them indispensable across various sectors.

Table of Contents

What is a Conveyorized Washing Machine?

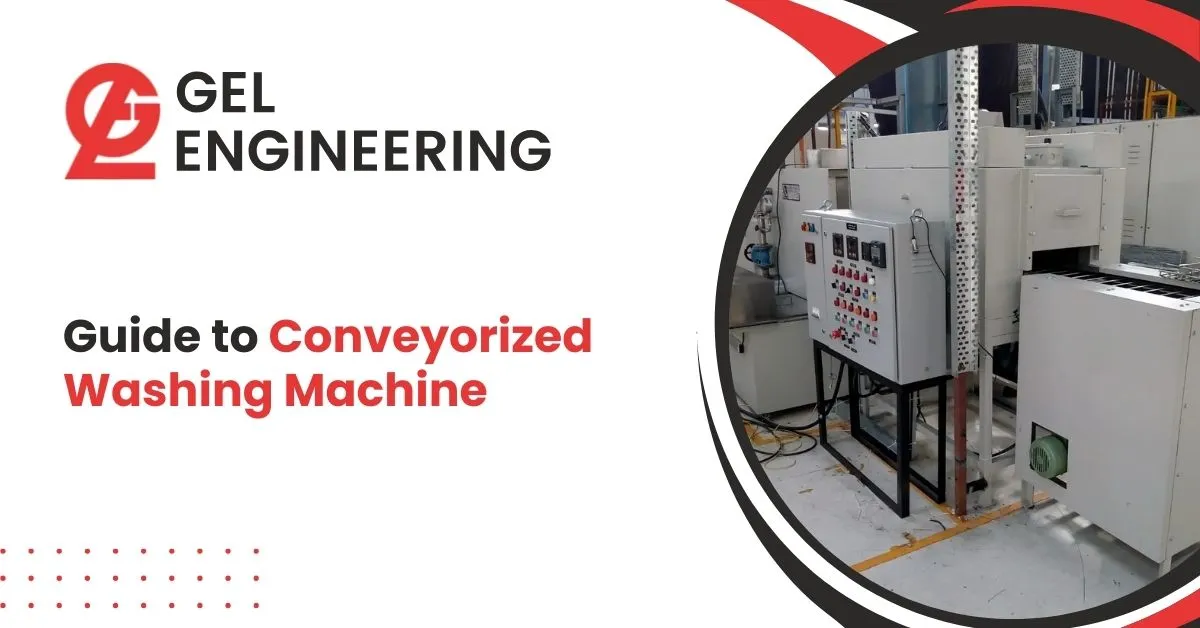

A conveyorized washing machine is an industrial parts washing machine equipped with a conveyor belt to transport parts or components through multiple cleaning stages. These stages may include pre-wash, main wash, rinse, drying, and sometimes additional treatments such as ultrasonic cleaning or surface finishing.

How Do Conveyorized Washing Machines Work?

Conveyorized washing machines and industrial parts washing machines are designed to clean a continuous flow of components. The process includes:

- Loading: Parts are placed on the conveyor belt, which moves them through the system.

- Cleaning Stages: Depending on the setup, the system may use high-pressure spray nozzles, immersion tanks, or ultrasonic cleaning for thorough cleansing.

- Rinsing and Drying: Components pass through rinsing zones to remove detergents and debris, followed by heated air drying or vacuum drying.

- Unloading: Clean parts are delivered at the output end, ready for use or further processing.

Key Features of Conveyorized Washing Machines

- Automation: Minimal manual intervention reduces errors and labour costs.

- Customizable Design: Machines can be tailored for specific components, cleaning agents, and industries.

- Energy Efficiency: Advanced systems use energy-efficient motors and water recycling technologies.

- High Throughput: Ideal for large-scale cleaning requirements.

Industries That Benefit from Conveyorized Washing Machines

- Automotive: Cleaning engine components, gears, and metal parts.

- Aerospace: Precision cleaning of turbines and aviation parts.

- Pharmaceuticals: Sterilizing medical equipment and containers.

- Electronics: Removing contaminants from PCBs and micro components.

- Food Processing: Sanitizing trays, utensils, and conveyor belts.

Need Industrial Parts Washing Machines? Contact Us Today for High-Quality and Efficient Options!

Advantages of Conveyorized Washing Machines

- Enhanced Cleaning Quality: Multi-stage processes ensure thorough cleaning and drying.

- Time Efficiency: Continuous cleaning boosts productivity and minimizes downtime.

- Eco-Friendly Operation: Recycling systems for water and cleaning agents reduce environmental impact.

- Cost Savings: Automation lowers labour costs and operational expenses.

- Scalability: Easily adaptable to increased production demands.

Choosing the Right Conveyorized Washing Machine

When selecting a conveyorized washing machine or industrial parts washing machine, consider:

- Material Compatibility: Ensure the system is suited for the materials being cleaned.

- Cleaning Requirements: Determine whether spray, immersion, or ultrasonic cleaning is needed.

- Throughput Capacity: Match the system’s speed to your production needs.

- Space and Energy Constraints: Choose compact, energy-efficient models for smaller facilities.

Future Trends in Conveyorized Washing Machines

With advancements in technology, conveyorized washing machines and industrial parts washing machines are becoming smarter and more efficient. Integration of IoT, AI-based monitoring, and eco-friendly cleaning agents is shaping the future of industrial cleaning.

Why Invest in a Conveyorized Washing Machine?

Investing in a conveyorized washing machine or industrial parts washing machine enhances operational efficiency, ensures superior cleaning quality, and helps industries meet stringent cleanliness standards. Whether you’re in automotive manufacturing or pharmaceutical production, this system streamlines your processes and boosts productivity.

Frequently Asked Questions

Which industries use conveyorized washing machines?

They are commonly used in automotive, aerospace, pharmaceuticals, electronics, and food processing industries.

How does a conveyorized washing machine work?

It transports parts through cleaning stages like pre-wash, main wash, rinsing, and drying using a conveyor belt system.

What are the benefits of conveyorized washing machines?

They offer consistent cleaning, high throughput, energy efficiency, and reduced labour costs.

Can conveyorized washing machines be customized?

Yes, they can be tailored to meet specific cleaning requirements, component types, and industry needs.

Are conveyorized washing machines eco-friendly?

Many models include water recycling and energy-efficient features, reducing their environmental impact.

Conclusion

Conveyorized washing machines and industrial parts washing machines are game-changers for industries requiring high-precision cleaning. With their ability to handle large volumes while maintaining efficiency, they are essential assets for modern manufacturing units.