In industrial spray painting, finish quality depends not only on paint material and technique but…

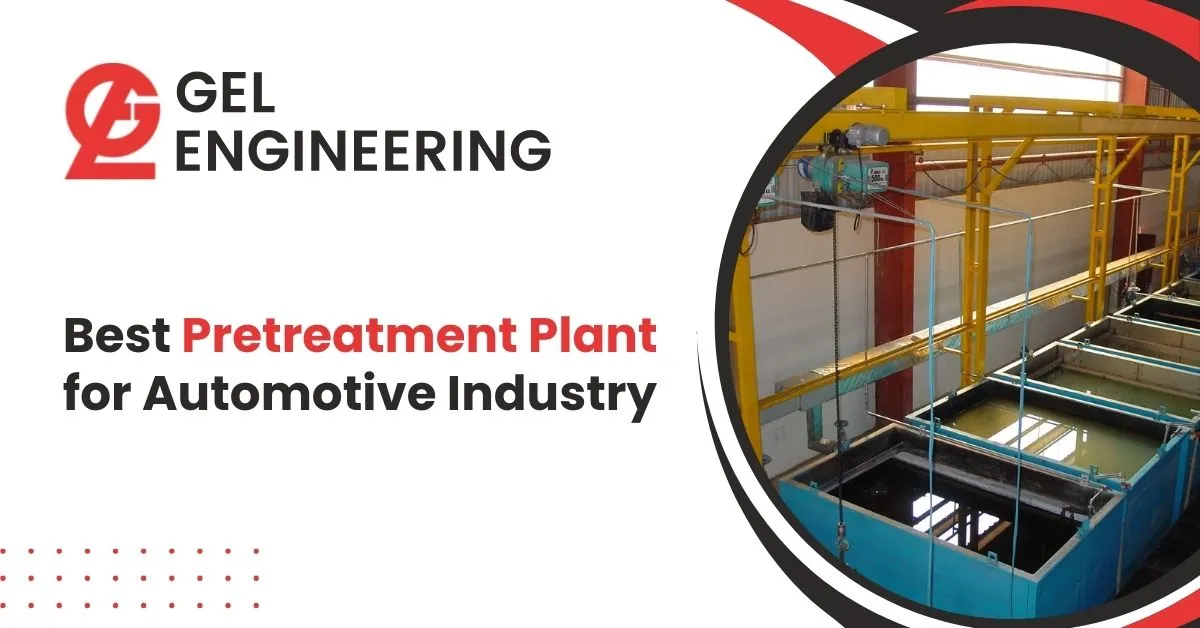

The automotive industry demands precision, efficiency, and durability in every process—and surface treatment is no exception. Pretreatment plants are essential for preparing metal surfaces before painting or coating, ensuring superior adhesion and long-lasting protection against corrosion. Whether you’re a manufacturer of cars, motorcycles, or heavy vehicles, a high-quality pretreatment plant is indispensable. Let’s explore why pretreatment plants are crucial and what makes them the best fit for the automotive sector.

Table of Contents

What is a Pretreatment Plant?

A pretreatment plant is a specialized system designed to clean and prepare metal surfaces for further processing, such as painting or coating. The plant removes contaminants like grease, rust, and dirt while conditioning the surface for optimal adhesion. This ensures a durable, corrosion-resistant finish that meets the stringent quality standards of the automotive industry.

Importance of Pretreatment Plants in the Automotive Industry

Pretreatment plants are vital in automotive manufacturing, ensuring proper surface preparation for coatings that enhance adhesion, corrosion resistance, and product longevity. These plants are essential for achieving high-quality, durable automotive components.

- Enhanced Adhesion: Proper pretreatment creates a uniform surface, allowing paints and coatings to bond effectively.

- Corrosion Resistance: By eliminating impurities and applying protective layers, pretreatment extends the lifespan of metal components.

- Consistent Quality: Ensures that every part meets the high aesthetic and functional standards expected in automotive manufacturing.

- Eco-Friendly Solutions: Modern pretreatment plants use advanced technologies to minimize waste and comply with environmental regulations.

Types of Pretreatment Plants for Automotive Applications

There are two main types of pretreatment plants—spray type and dip type—each designed to meet the specific needs of automotive manufacturers depending on part geometry and treatment depth. Choosing the right system optimizes surface preparation efficiency.

Spray Type Pretreatment Plant:

- Utilizes high-pressure spray nozzles to apply chemicals to metal surfaces.

- Ideal for large volumes and complex geometries.

- Provides uniform treatment and faster processing times.

Dip Type Pretreatment Plant:

- Involves immersing parts in a series of chemical baths.

- Suitable for simple geometries and components requiring deep chemical penetration.

- Ensures thorough cleaning and surface preparation.

Ready to elevate your automotive manufacturing process? Explore our advanced pretreatment plant solutions to enhance product quality and efficiency today. Contact us Now!

Key Features of the Best Pretreatment Plants

The best pretreatment plants incorporate advanced chemical application systems, automation, and energy-saving technologies, all designed to deliver consistent results while adhering to environmental standards. These features ensure high performance and long-term sustainability.

- Advanced Chemical Application: State-of-the-art systems ensure even coverage and optimal results.

- Customizable Configurations: Tailored designs to meet the unique needs of automotive manufacturers.

- Energy Efficiency: Incorporates energy-saving mechanisms to reduce operational costs.

- Automation: Fully automated processes for improved efficiency and reduced labour requirements.

- Environmental Compliance: Designed to adhere to stringent environmental standards, including water recycling and waste management systems.

Benefits for Automotive Manufacturers

Using top-tier pretreatment plants offers numerous advantages, including enhanced product durability, cost reduction, and faster production times. Their versatility and efficiency contribute to the overall success and profitability of automotive manufacturers.

- Improved Product Durability: High-quality finishes provide long-term resistance to environmental wear and tear.

- Reduced Costs: Minimizes rework, waste, and material usage.

- Versatility: Suitable for a wide range of automotive components, from body panels to intricate parts.

- Faster Turnaround Times: Automated processes and efficient designs accelerate production cycles.

Why Choose Gel Engineering for Your Pretreatment Plant?

At Gel Engineering, we specialize in designing and manufacturing cutting-edge pretreatment plants tailored for the automotive industry. With decades of experience, we offer solutions that combine efficiency, precision, and sustainability.

- Custom Solutions: From compact systems to large-scale plants, we deliver bespoke designs to match your production needs.

- Expertise in Automation: Our advanced automation ensures seamless integration into your production line.

- Eco-Friendly Approach: We prioritize sustainability with energy-efficient and waste-minimizing technologies.

- Proven Track Record: Trusted by leading automotive manufacturers worldwide.

Frequently Asked Questions

What is a pretreatment plant in the automotive industry?

It’s a system for cleaning and preparing metal surfaces to ensure better paint adhesion and corrosion resistance.

What are the types of pretreatment plants available?

Spray Type (high-pressure application) and Dip Type (chemical immersion).

Why is pretreatment important for automotive parts?

It enhances durability by improving paint adhesion and preventing corrosion.

Can pretreatment plants be customized for specific needs?

Yes, they can be tailored to handle different part sizes, volumes, and requirements.

Conclusion

Investing in the best pretreatment plant is a game-changer for automotive manufacturers, ensuring superior finishes, enhanced durability, and cost efficiency. With innovations in technology and a commitment to quality, pretreatment plants are indispensable for achieving the high standards of the automotive industry.